VACUUM HARDENING

High quality, traditional

precious metals products.

MAKING COINS MENU:

VACUUM HARDENING

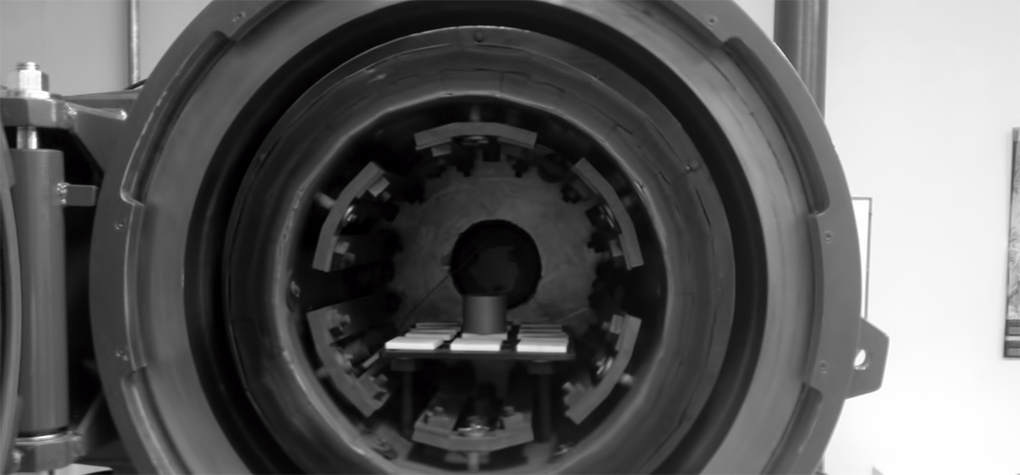

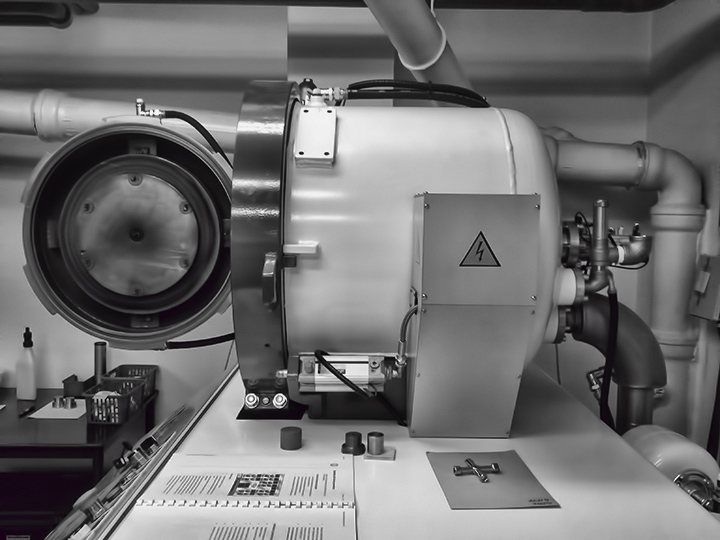

The mint dies are quenched in a vacuum furnace.

A vacuum die quenching belongs due to its high technical standard to “qualitative quenching”. In addition, a vacuum quenching is ecological, clean, and thanks to modern management units also economical. Its advantage is also higher speed of the process, and thus speed up the production.

![Vacuum quenching furnace]()

Vacuum quenching furnace

At higher temperatures, which usually occur in vacuum furnaces (normal quenching temperature of 850 ° C - 1200 ° C), the vacuum provides significantly better protection against decarburization. Even at quenching temperatures around 1300 ° C, dies are shiny metallic after quenching.

The mint dies are quenched in a vacuum furnace.

A vacuum die quenching belongs due to its high technical standard to “qualitative quenching”. In addition, a vacuum quenching is ecological, clean, and thanks to modern management units also economical. Its advantage is also higher speed of the process, and thus speed up the production.

Vacuum quenching furnace

At higher temperatures, which usually occur in vacuum furnaces (normal quenching temperature of 850 ° C - 1200 ° C), the vacuum provides significantly better protection against decarburization. Even at quenching temperatures around 1300 ° C, dies are shiny metallic after quenching.